- Design CAD-CAM: working capacity of 1200 hours per month.

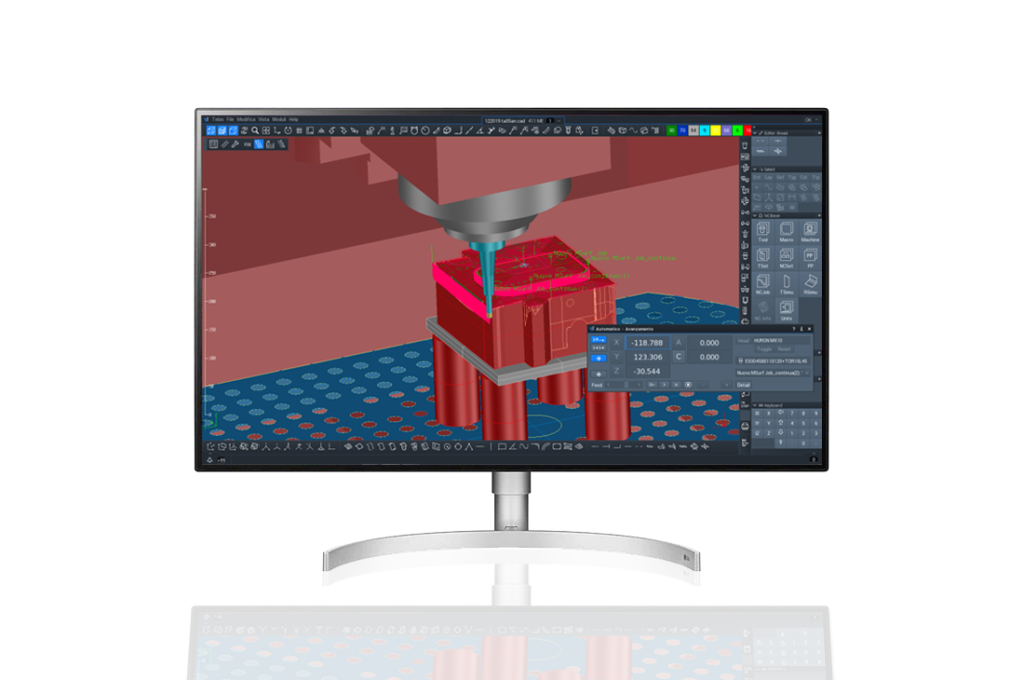

- CAD software: VISI

- CAM software: TEBIS

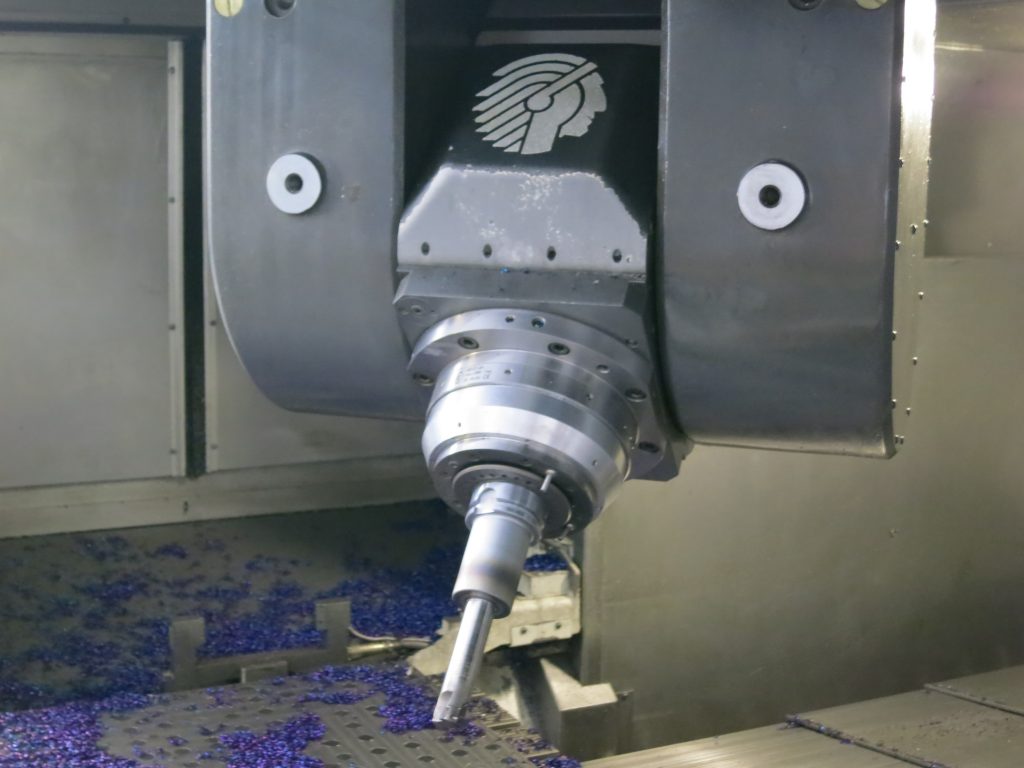

- No.2 5-axis milling machines

- No.1 milling machine 4-axis

- No.3 milling machines 3 -axis

- No.1 boring mill

- No.3 grinding machines

- No.3 die sinking EDM (Electrical Discharge Machine)

- No.1 wire EDM (Electrical Discharge Machine)

- No.2 lathes

- Working capacity of mold workshop: 4,000 hours per month

Maximum realization dimensions: 1800x1000x1000 mm

Total workshop area: 1.500 m²

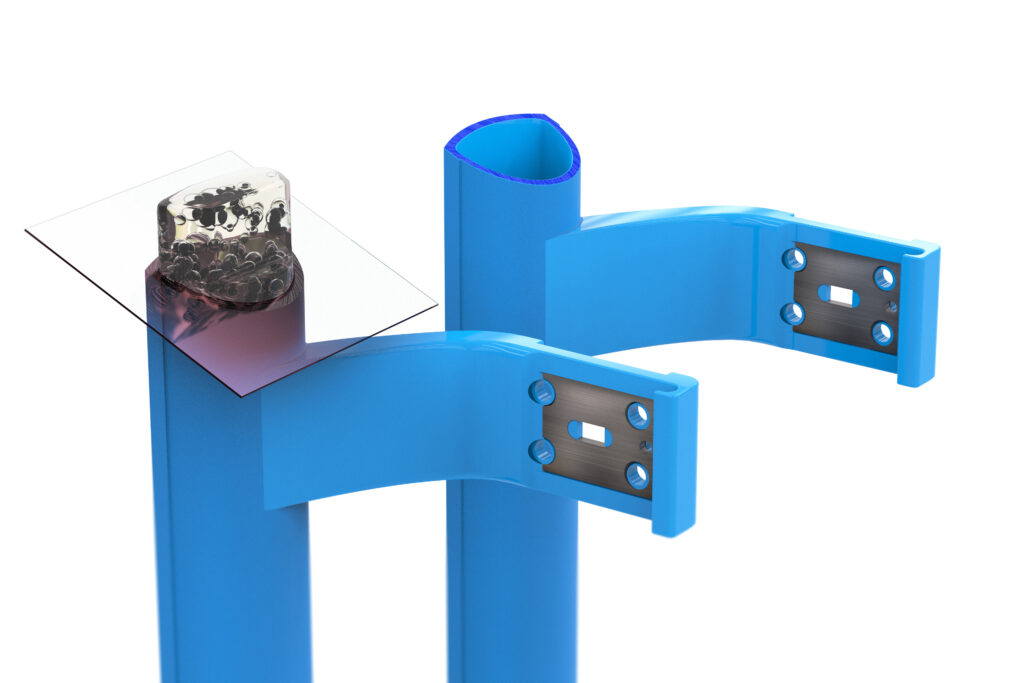

- Construction of single or multi-cavity molds with high technical and/or aesthetic characteristics.

- Construction of hot and cold runner injection molds

- Construction of rotary, sliding and blade-moving molds for the creation of products using traditional or dedicated press machines

- Construction of gas technology injection molds: GAIM

- Construction of molds dedicated to the molding of techno polymers and innovative plastic materials

- Construction of molds for co-molding of metal inserts, also fully automated for high productions

- Construction of molds according to customer specifications

Co-Design

We study our customers’ design ideas through an internal analysis aimed at improving the constructive and functional solutions of the product.

This phase is followed by the simulation of the production processes as to identify critical issues and plan all phases of the work:

Product geometries

- Injection points

- Molding mode

Maintenance

Scheduled and extraordinary mold modifications and maintenance

Support to the internal molding department

Short feedback timing for restoring production anomalies

1 million shots warranty

Possibility of creating molds that guarantee high productivity, up to one million shots

0

Million euros – Total turnover (2022)

0

Employees

0

Clients

0

Industries we serve

0

Molds designed in 60 years

Our Best Clients