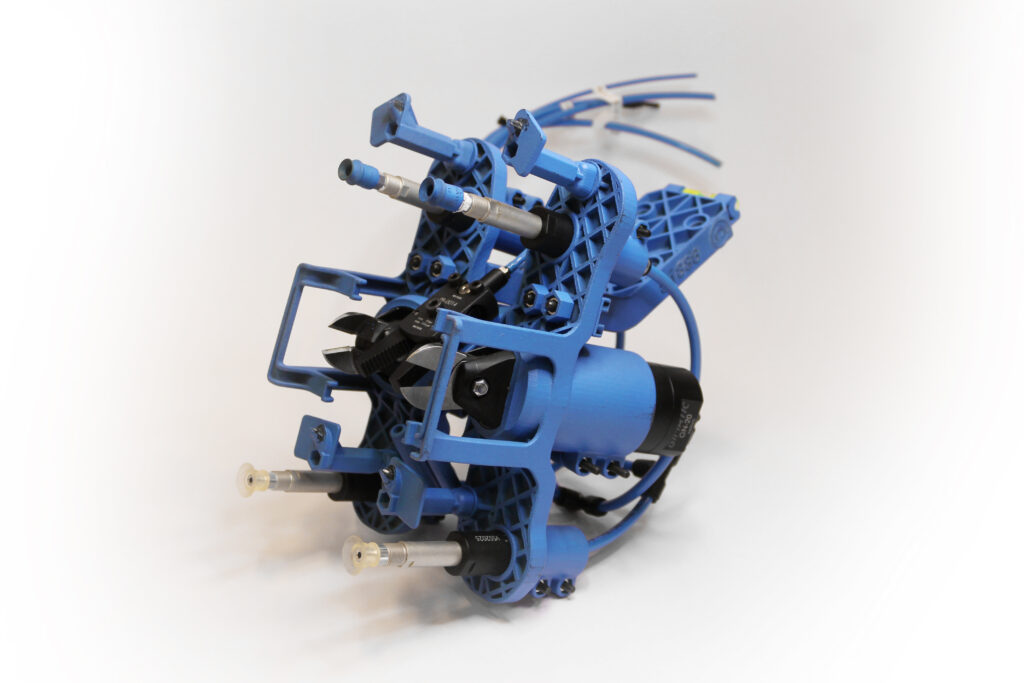

The gripping hand, with an IT patent and in the process of an EPO patent, is designed together with the mold and created using additive technologies (3D printing) in order to optimize the entire tooling and automation process by reducing the workforce.

Problems to be solved

The gripping hands available on the market today have functional limitations that expose companies to the following unsatisfied needs:

- Accuracy of picking during the extraction phase from the injection press to avoid damaging the molded part.

- Reduction of the cycle time of the injection press without modifying the plastic parameters.

- Reduction of robot setup times.

- Reduction of operator time for quality checks or modification of molded pieces.

- Lightening of the weight of traditional “gripping hands” so as not to overload the robot arm itself.

- Additional costs and cycle times for equipment needed after picking, for example for cutting the sprue itself.

Our answer

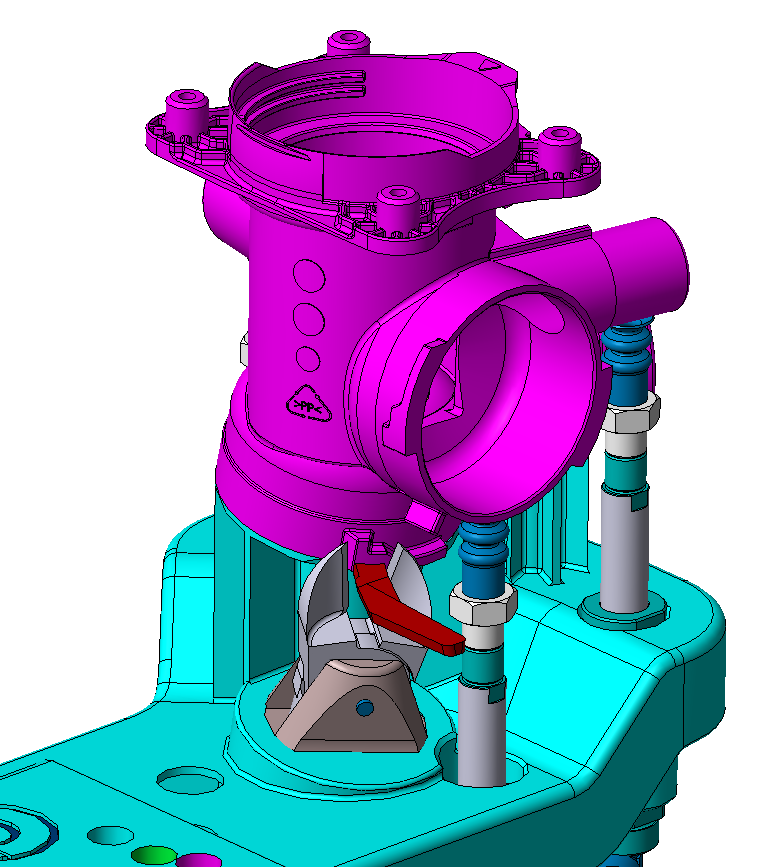

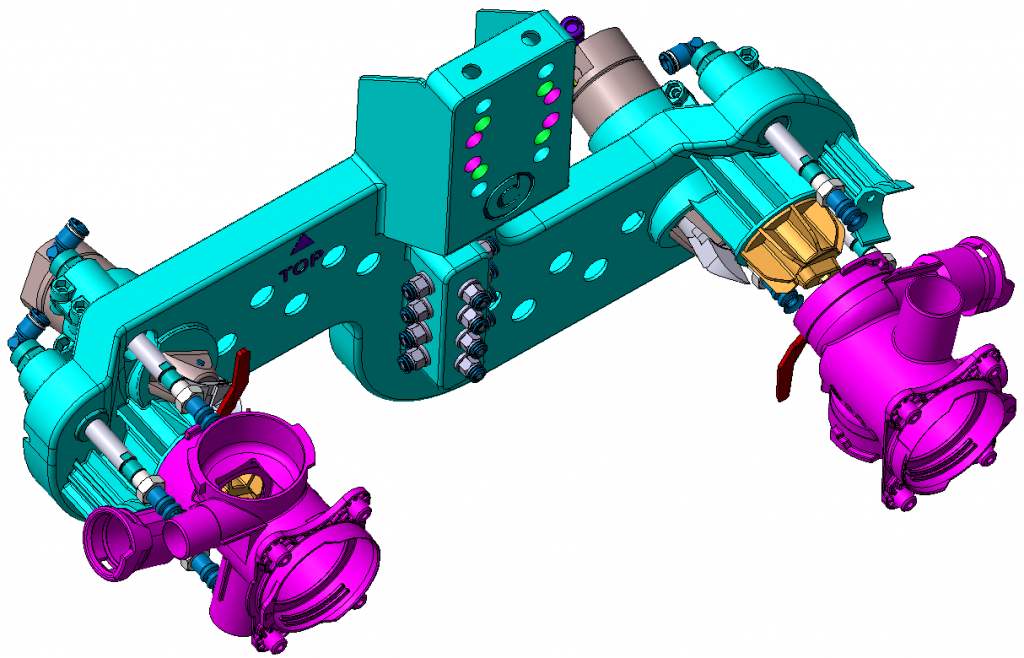

The gripping hands (IT patent, EU patent pending) by Casagrande Srl are designed in CAD on the 3D model of the mold to which they refer; thus, allowing the vision of the kinematics of the mold including the extraction of the piece and the functioning of the gripping hand, all with a real vision of the process.

The creation of the structure takes place with 3D printing technology which allows the structure of the gripping hand to be obtained quickly and at low cost with the perfect mold of the product and with the perfect position of the actuators necessary for handling the piece (suction cups, pliers , wire cutters, optical lasers, etc.)

Advantages

- Precise picking of the part for extraction from the press.

- Less waste due to instability and imprecision of the gripping hand with traditional systems.

- A greater speed of escape of the robotic arm from the press space with the consequent reduction of molding cycle times

- Contemporaneity and precision of sprue cutting and other quality controls during overflight and filling downtime.

- Very reduced gripping hand setup times for press costs’ benefit

- Quick and easy replication in case of breaking and without any control or adjustment in the machine. Each replica is identical to the project.

- Machine downtime caused by rough extraction has been reduced to almost zero. Operator and toolmaker times have been optimised.

- Use of robots with Payloads that are not oversized for the weight of the end effector.

Competitive advantage

The customization of the gripping hand according to the product also allows intrinsic protection for the molding company as it becomes more competitive for its competitors and strengthens the relationship with its customer due to the strategic link between the gripping hand, the mold and the molding process.